Personalised Implants is an open innovation community where academic hospitals, knowledge institutes, SME’s and startups in the Northern Netherlands work together to deliver solutions tailored to the patients and to overcome shared challenges identified in the regular workflow for design and production of personalized implants.

Medical implants are regularly used to fix and repair bone fragments in the human body. However, the current standard implants have a large number of limitations. Because there is so much diversity between people, type of injuries and bone fractures, there are no customized implants available to treat these conditions optimally. All of this leads to a long surgical and recovery time with an increased risk of infection, inaccuracy, material failure and reduced functional recovery of the patient. In addition, new European regulations for medical devices (MDR) and in vitro diagnostics (IVDR) have been drawn up. The legislation imposes complex requirements on the production conditions of implants. The new rules will affect manufacturers, importers and distributors of medical devices, healthcare institutions, healthcare providers and (indirectly) patients.

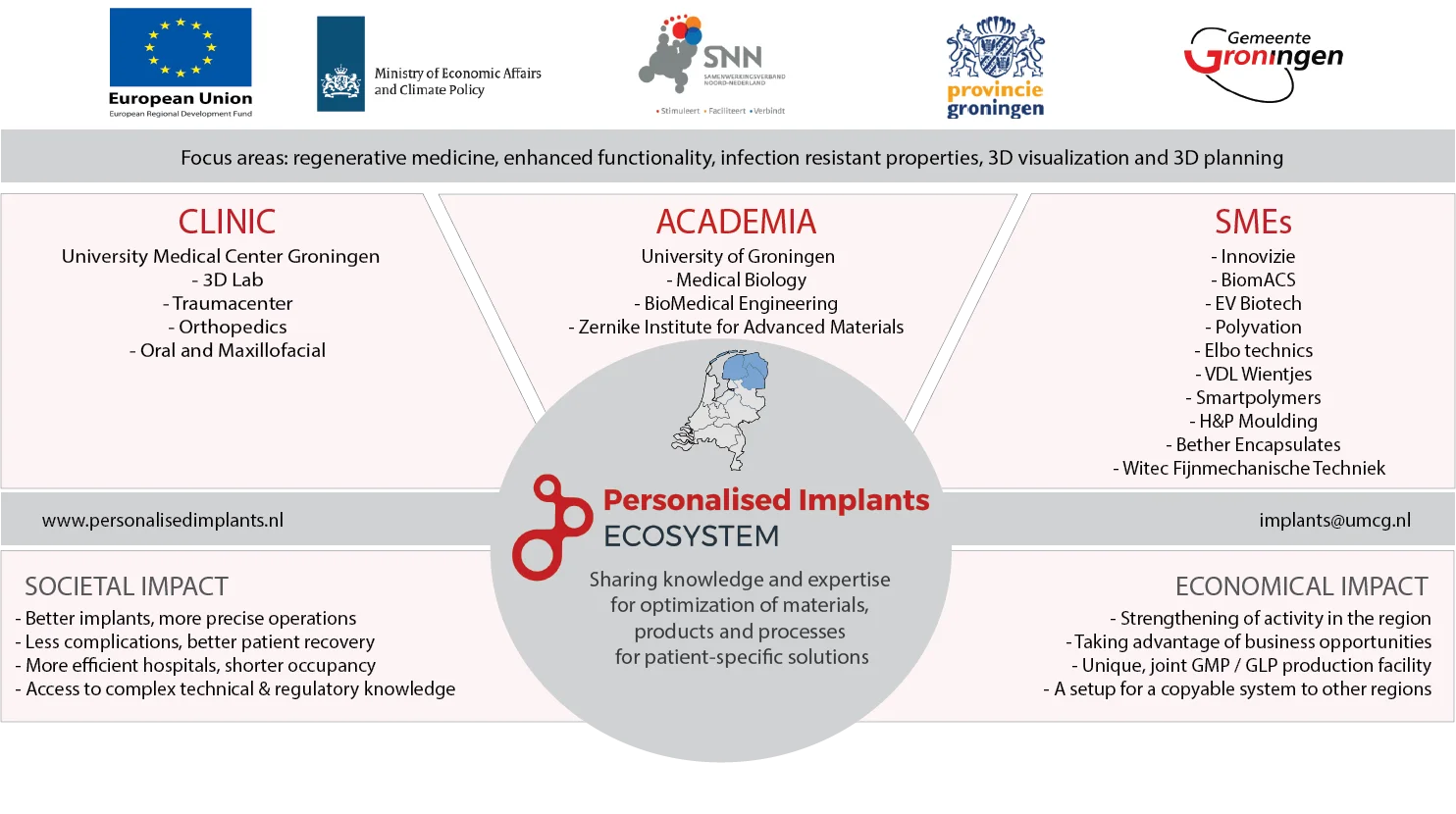

The creation and placement of an implant is a sequence of different specializations such as: materials science, biomechanics, manufacturing technologies (including 3D printing), IT and visualization technology, clinical research and specialized surgeons. Therefore, the Personalised Implants ecosystem in the Northern Netherlands was created in 2019 with the goal of bringing together different manufacturer and R&D companies, the UMCG and the University of Groningen that will work together to seize innovative solutions to improve the current implant workflow in all his steps, including the selection of the biomaterials to use, the designing, the production and the medical procedures for generation of personalized implants within a few days from the time a seriously injured patient is hospitalized.

The open innovation ecosystem initiates and implements innovative projects to deliver patient-specific solutions through the joint expertise of its multidisciplinary partners in optimization of materials, production and processes for implant design and manufacturing.

The ecosystem partners joint efforts to design patient specific solutions with the main aims of:

The creation and placement of an implant is a sequence of different specializations such as: materials science, biomechanics, manufacturing technologies (including 3D printing), IT and visualization technology, clinical research and specialized surgeons. Therefore, the Personalised Implants ecosystem in the Northern Netherlands was created in 2019 with the goal of bringing together different manufacturer and R&D companies, the UMCG and the University of Groningen that will work together to seize innovative solutions to improve the current implant workflow in all his steps, including the selection of the biomaterials to use, the designing, the production and the medical procedures for generation of personalized implants within a few days from the time a seriously injured patient is hospitalized.

The innovation projects are supported by the Open Innovation Subsidy that has been made available by Samenwerkingsverband Noord-Nederland (SNN), Ministerie van Economische Zaken en Klimaat en het Europees Fonds voor Regionale Ontwikkeling (EFRO), with further support from the Province of Groningen and the Municipality of Groningen.

If you have an idea for a project that is developing around patient-specific implants, the testing of new biomaterials, IT solutions and production systems or if you want to connect with the Northern Netherlands ecosystem partners, we invite you to contact us at implants@umcg.nl.

Are you interested to know more and connect? Please visit our contact page or follow us on our social channels: @PIecosystem (Twitter) and Personalised Implants Northern Netherlands (LinkedIn).